Preparing the site for a house: Step by step

Building a house is an exciting endeavour, but before we can enjoy our dream, the site needs to be properly prepared. How do you do this, paying particular attention to the construction of prefabricated timber houses and crane assembly?

1. Site selection and preparation

The first step is to choose a suitable site. It should meet our requirements in terms of location, size and access to utilities (water, sewerage, electricity and other utilities). Check the local plan at the local authority so you know what can be built on the parcel.

Also check the plot with regard to the possible orientation of the future building with respect to the world. It is best to have the terrace on the south side. This gives us the longest exposure to sunlight. In winter, we can thus obtain free heating for the largest parts of the house.

The location of the site itself is not everything. It is worth paying attention to the vegetation found on the plot of land. Some plants may indicate that the parcel is periodically waterlogged, which needs to be taken into account in the foundation height of the building. It is also worth checking the immediate surroundings. Access to the public road, width of access, easement of access. It is also good practice to talk to the neighbours.

Once you have found the ideal site, you need to prepare the area:

Removal of vegetation: You need to remove trees, shrubs and other vegetation on the site of the building foundation. In some cases, you may need to obtain the necessary permits. It is worth hiring a professional company for this task to avoid damage to underground infrastructure such as pipes or cables.

Land levelling: The plot of land must be properly levelled to provide a stable base for the foundations.

Depending on the terrain, this may require additional earthworks, such as earth embankment or slope creation.

Geotechnical investigations: Before starting building work, it is worth carrying out soil investigations to ensure that the ground is sufficiently stable and that there are no groundwater problems. These tests allow you to assess the load-bearing capacity of the soil and to determine whether there are any soil layers that could cause the building to settle.

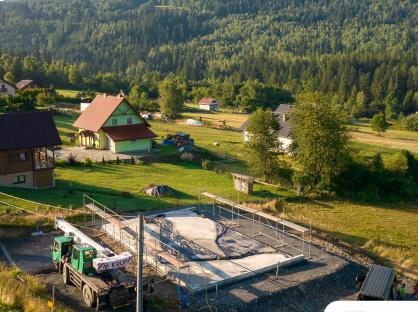

2. Preparing the foundation slab

Timber prefabricated houses usually require lightweight foundations, which is one of their advantages. BOX HAUS usually uses foundation slabs. The slab design allows it to distribute loads over a larger area of ground. It is quick to construct. There is no need to pour footings separately, build concrete blocks or make the so-called slabs.

Slabs for simple buildings with good ground conditions can be ready even in 3-4 days.

How long after the slab has been poured can the house be assembled? It is assumed that in good weather conditions, a house can be assembled without any worries after two weeks. The process can take up to several weeks, depending on the weather conditions and the specifications of the concrete. During this time, it is a good idea to water the concrete regularly to avoid it drying out and cracking too quickly.

If the conditions on the plot of land do not allow for the use of a foundation slab or this is the wish of the Investor - BOX HAUS also assembles houses on traditional foundations, cellars, piles, etc.

3. Assembling the prefabricated elements

When the foundations are ready, the assembly of the wooden prefabricated elements can begin. The whole process is quick and efficient thanks to the use of modern technology.

Transporting the prefabricated elements: The house elements are transported to the construction site. These are usually walls, ceilings and other components prepared in advance in the factory.

Transport must be well organised so that the components arrive at the construction site intact. It is worth paying attention to the protection of the prefabricated elements against mechanical damage and the effects of weather conditions.

Assembly using a crane: The precast elements are placed on the foundation slab using a crane. This is a key stage that requires precision and experience. The crane lifts the heavy elements and places them in the right places according to the design. This process requires careful coordination of the workers to ensure that all elements are correctly installed and stable. With the use of a crane, installation is quick and efficient, minimising the risk of delays due to adverse weather conditions.

4. Finishing the house

Once the prefabricated elements have been installed, we can move on to the finishing work:

Installations: We install mechanical ventilation with heat recovery (recuperation), electrical, water, multimedia, alarm and heating systems.

Finishing works: this includes insulating the roof, installing ceilings, plastering and painting the walls.

Summary:

Building a prefabricated timber house is a quick and efficient way to realise the dream of having your own place on earth. It is crucial that the site is properly prepared to ensure the stability and durability of the building. With the use of a crane, the assembly of the prefabs is precise and efficient, allowing the building work to be completed quickly. Now that you know the basic steps, you can confidently start planning your investment! Remember that a well-organised construction process is the key to success and satisfaction with the end result.